As a VNITian, you guys might have observed that VNIT stands

out from Nagpur city when it comes to power cut. Power cuts are rare and even

when there is a power failure due to some fault we have supply for our mess and

in exam time in our hostel even. Wouldn’t it be interesting to know how the

electrical distribution and substations our college are configured meets the

demand of uninterrupted supply? Let’s find out!

VNIT receives a special treatment when it comes to power

supply, thanks to our director who presented our college as a research

institute which requires 24 hours uninterrupted power supply in front of Chief

Minister. As a result our college was given a separate 11kv line from MSCDCL

which parts it from the rest of Nagpur city.

Overview

There are 3 substations within campus – Substation A, B,

C. The 11kv 3phase supply is directly

received at Substation A. From there we have 11kV feeder running to Sub B and

C. For the purpose of distribution it is first step down to 440V. Single phase

lines of 230 V are distributed among the various loads (department, hostel,

lab, library etc.).

For the purpose of backup each substation is equipped with 250kVA diesel generator. Its kVA rating is not enough to drive both the departments as well as the hostel at the same time. So it is usually switched between them depending upon the requirement. During day time, most of are gone for classes so in case of power failure, diesel generator if run supplies to the department only. Whereas at night, the authorities give priority to water pumping and then to the mess and the hostel.

In VNIT you won’t find overhead cables. The large number of trees falling during rainy season leading to interruption in power supply plus increased maintenance expenditure had forced the authorities to shift all the cables underground.

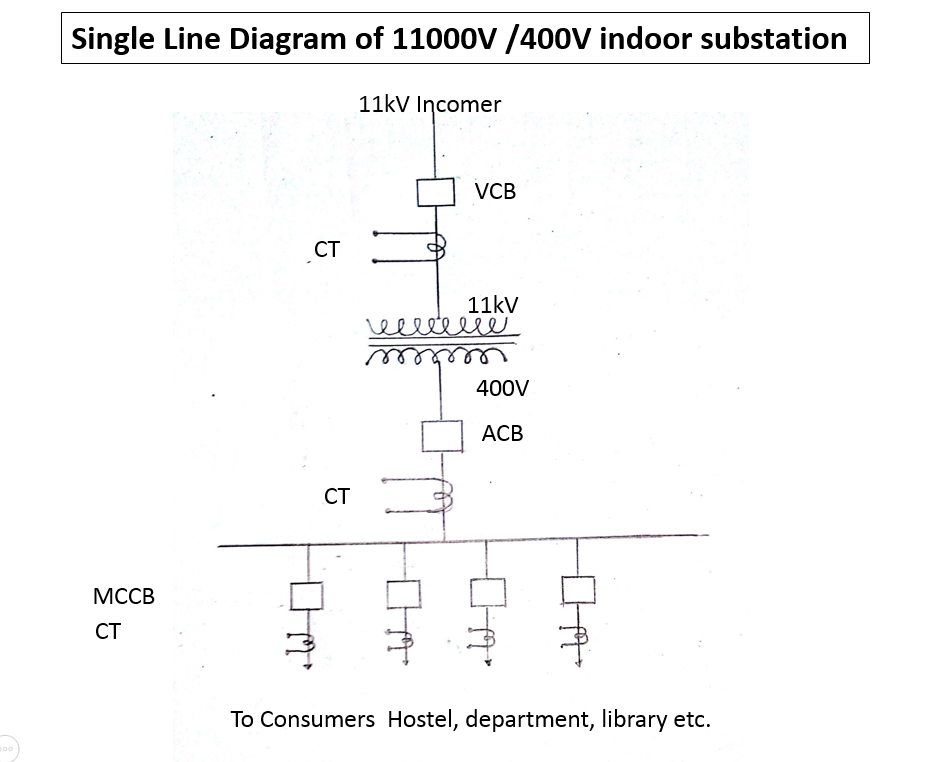

Single line Diagram

Main Components of 11kV substation:

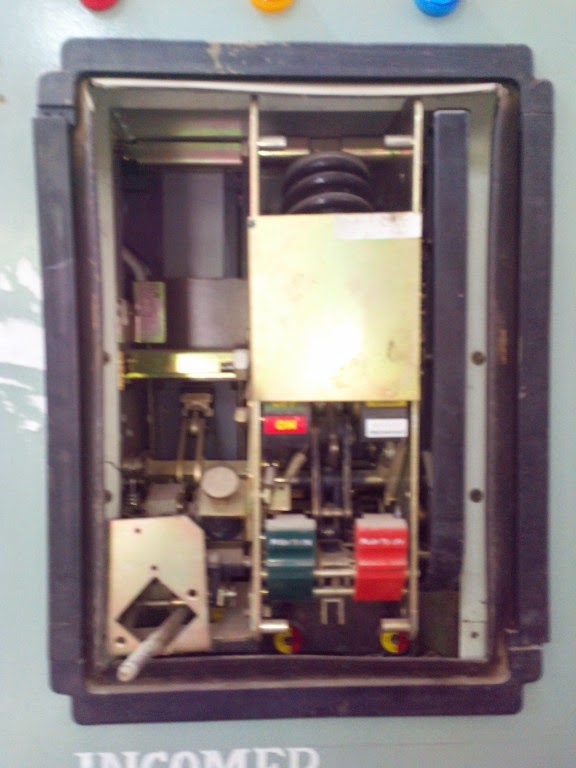

Circuit Breakers:

Circuit breaker does the task of on load making and breaking of the circuit. This task can't be done in open air for high voltage as it leads to arcing as a result of ionization of air.

There are different type of circuit breakers :

- Gas Circuit Breakers

- Oil Circuit Breakers

- Vacuum Circuit Breakers

- Air Circuit Breakers

Panel installed above it are for monitoring of relay protection, tripping etc.

Other advantages of Vertical isolation VCB are :

- A time tested product for high reliability

- Motorized spring charging mechanism

- Cost effective solution by add-on protective devices like Series tripping coils.

- Portable earthing device for busbar feeder earthing

- Comprehensive range of electrical & mechanical interlocks

For lower voltage level ie. at the distribution end, MCCB of 250A rating are installed on each phase (Phase Voltage =230V). There are air circuit breakers which uses arc chutes for extinguishing of the arc produced during the process.

Current Transformers:

Current transformers are installed at various stages in a network. Current transformers serve two basic purposes :- Measurement of current

- Driving Protection relays

For measurement purposes we 200:1 or 400:1 etc rating.

Transformer:

Transformer is a constant flux device used for changing the ac voltage level.

Each substation has two 400kVA 11kV/400V delta - star step down transformer of which one of them is standby in case some problem occurs. It is provided with ONAN type of cooling.

Auxiliaries attached to transformer:

1. Conservator : The above described transformer is filled with 310Kg of oil for the purpose of cooling. Due to heating of the oil, oil will expand. If space is not provided to allow expansion, the transformer will burst. To prevent such scenario from being created, conservators are installed on the top of the transformer to allow expansion.

2. Buchholz relay: Buchholz relay is a mechanical actuator, which trips the transformer in case of internal faults like insulation breakdown, short circuit of winding etc. Due to these faults the temperature rises and there is decomposition of insulating oil and gases are produced which get accumulated in the upper part of the Buchholz relay. This leads to tilting of the mercury switch. Based upon the level, the alarm is produced and relay comes in action.

3. Silica Jell :One of the biggest enemy of transformer is the moisture. To deal with these, the transformer are provided with silica jell box. It is blue in colour. As it absorbs moisture it becomes pinkish. Then it is required to be replaced. They can be reused after placing them in light for some time. They lose their moisture content and become blue again and ready to be reused. However with every use the silica content keeps on getting reduced so it can't be used infinitely and needs to be replaced with new one.

4. Various other components such are thermometer, pressure release valve, tap changer are present to ensure smooth functioning of the transformer.

Capacitor Bank:

Capacitor Bank is installed in each substation to improve the power factor. Power factor is keep close to 1 usually .99 by using different combination of 25kVAR and 50kVAR of Capacitors.Distribution Panel:

Distribution Panel contains panels containing Circuit Breakers for each department, hostel etc. so that the can be switched on and off depending upon the requirement.Diesel Generator Set:

To ensure uninterrupted supply in case of power failure within the campus, each substation has a 250kVA Diesel Generator Set. Since it is less than 400kVA transformer that are meant to power the campus, the DG set is incapable of powering the normal load at once. So usually power is restored depending upon the requirement as stated earlier.

DG set installed is a GPW250 model Greaves power 50Hz DG set of dimension 4*1.8*2.15 (m). It is a 3 phase generator set with operating power factor of 0.8 and maximum load current capacity of 347.8A at this power factor. It has 24V, 2*180AH battery required for its starting up. Integral fuel tank capacity provided is 420L. It uses water as coolant.

DG set comprises of two main parts:

1. Diesel Engine

2. Alternator

Diesel Engine:

Diesel Engine:It is a 6 cylinder, TBD3V8 Greaves model rated at 1500rpm and output of 313HP. It has lub oil sump capacity of 29L and Greaves Maxtherm API CF is used as lub oil. For starting the engine 24V battery is installed. AMF Panel is provided with a start button to start the generator remotely. However before this the Changeover should be moved from the transformer side to the diesel engine side. It is used as prime mover for the alternator.

Alternator:

The shaft of the diesel engine is connected to a 3 phase, 4 poles brush-less generator of 250kVA, 415V and power factor of 0.8. It is provided with IP23 protection and class-H insulation.

Other features :

- Ease of maintenance with integrated components and outboard Exciter/Rotating Rectifier.

- A reliable long life with superior class 'H' insulation.

- Higher motor starting capability.

- Compact, light and sturdy die cast aluminum stator for frames upto 250, offer superior finish.

- High thyristor load withstand capability for Cell-Phone and Telecom applications.

- Short circuit withstand capability.

- Wide range of coupling discs / adaptor for single bearing construction suitable for wide range of Engine makers.

Additionally there is air cleaner pumps for proper functioning of the DG set. Also we have various meters for oil level, water temperature, battery charge indicator etc for monitoring the health of the set. The whole DG set is provided with an acoustic enclosure to prevent noise pollution. Also regular maintenance is done to extend the life of the DG set.

And lastly an important question!! Ever wondered what's the electrical bill of our campus??

It's 30 lakhs per months!! So when they ask us to save electricity, they do actually mean it.

Substation is integral part of a power system and form important links between the generating station, transmission systems, distribution systems and the load points.

ReplyDeleteTransformer Manufacturer in India

Nice Info.

ReplyDeleteCompact Substation in Hyderabad

good blog

ReplyDelete